I’m Doing Some Repairs on my Boat. Can I Use Pressure Treated Plywood Instead of Marine Plywood for Coring?

A comparison to illustrate why these plywoods are not interchangeable.

Marine Plywood

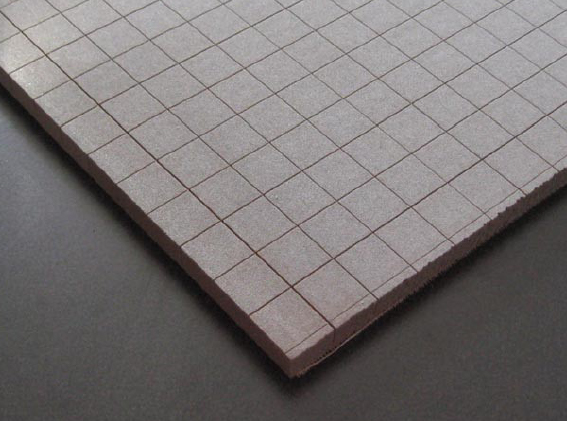

- Assembled gap and void-free in all layers.

- Laminated under pressure.

- Uses special, water-proof glue that holds the layers together.

- Constructed of harder woods which have a natural water resistance.

- Stronger and more durable because it has more thinner layers of hardwood.

- Water has no effect on the glue or the strength of the lamination.

- Will not easily delaminate, bubble, buckle, or warp.

- If cut no voids or gaps will be discovered on the cut edges.

- If finished appropriately, will outlast pressure-treated plywood.

Pressure Treated Plywood

- Common plywood that has been pressure treated with chemicals.

- This treatment prevents the wood from decaying or rotting.

- Can also discourage insect damage.

- Pressure treatment with chemical compounds does not waterproof the plywood.

- Continuous exposure to water will leach the preservative chemicals from the wood.

- Often made with soft wood to enable the penetration of the chemicals.

- Softer woods will also allow for the penetration of water.

- Does not have the additional plies to add strength and durability.

- Does not eliminate all gaps or voids.

Marine plywood is specifically manufactured to stand up to the harsh marine environment. The materials used in in its construction are specifically chosen to assist in making it as water resistant as possible. Pressure treated plywood is usually regular softwood and will absorb moisture very easily.